Why it’s so important

Race cars have a stance that instantly catches and holds the eye. This effect is created by the relationship between the wheels and tires to the forms surrounding them. Aggressive, low, and ready to attack.

The Lola T70 Mk IIIB Coupe is one of racing’s most sensuous race cars. It relies on its stance to help accomplish that.

Blasting around a track is a delicate balance between driver intent and the laws of physics. Minute tire patches translate all the power and driver guidance to the ground. These flat spots are a result of the car’s weight and additional aerodynamic pressure.

TIRES

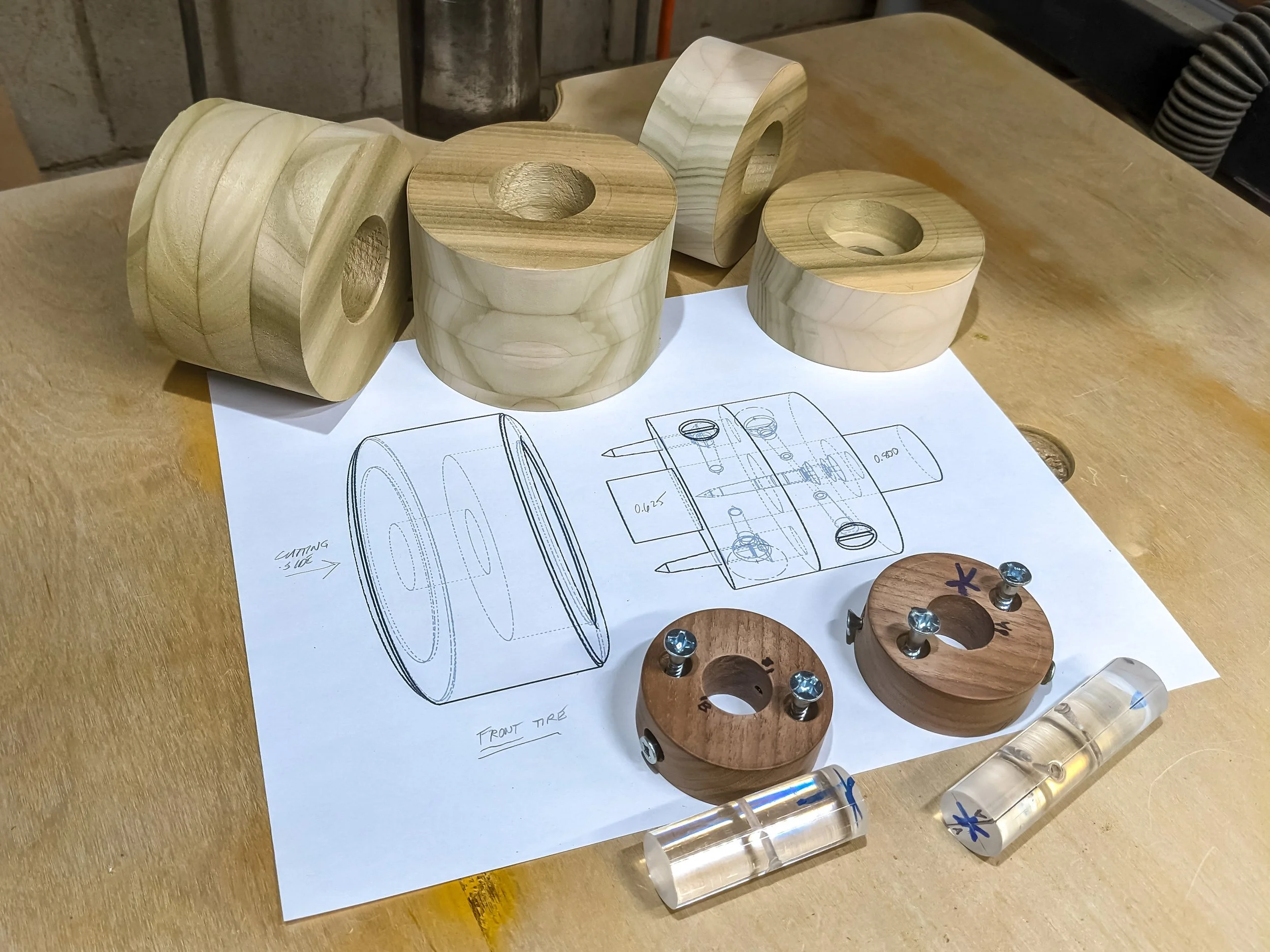

Tire jigs were critical to keep front and rear tire features concentric during turning.

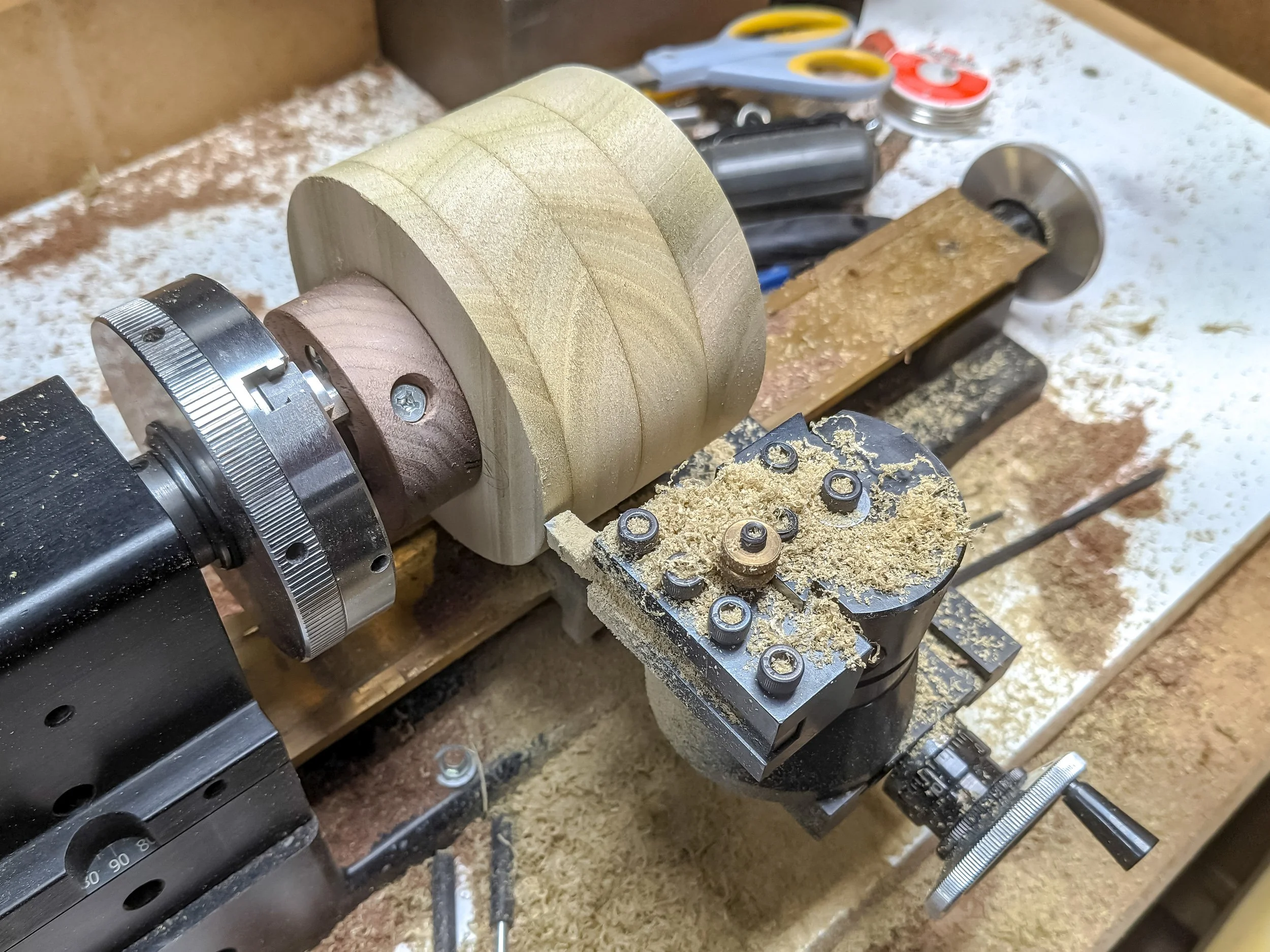

During fabrication a tire must first be made round. The lathe is the natural tool to accomplish this. Proper attention to the sequence of operations leads to concentricity of both inside and outside features.

The T70’s tires started with stacks of laminated poplar blanks; four for the rears and two for the fronts. Various features of the turning jig needed to center each tire on the lathe were worked out using CAD to ensure accuracy.

Axle holes in the blanks are used as the controlling feature. The acrylic jig axles have location features for the mahogany rings to lock in place.

Turning the outside features uses one ring that screws to the back of the blank. The inside features take two rings that are screwed into the blank from the front.

Cutting the outside diameter of a rear tire using a laminated poplar blank.

First the blanks were rough sanded to approximate size on a disk sander and then mounted on the lathe to be turned down to the final outer diameter (OD).

With the tool post mounted at its outer limit and the cross-slide also maxed out, turning the OD of the rear tires was a challenge to the rigidity of the lathe. Tool chatter had to be carefully controlled.

The rear tire OD is 3.35” (8.5 cm) and 2.25” (5.7 cm) wide. The fronts are smaller at 2.95” (7.5 cm) OD and 1.47” (3.7 cm) in width.

CAD drawings of 1/4’ (6.34 mm) tool steel profile tool for front tires.

Once the OD and the final size wheel diameter were turned it was time to add the tire profile. This was done with custom profile tools that I made from tool steel using the proper annealing, shaping, re-heating and quenching sequence.

One tool was needed for rears and another for the fronts. The details for the front tool are shown in the CAD drawings.

Each profile was cut by moving the profile tool into the face of the turning tire. Unlike man-made materials, the wood has a natural springiness that must be factored in.

First the outside profile was turned. Then the tire was reversed on the jig and the inside profile was done.

A separate post detailing the making of profile tools can be found here: Cutting Tire Profiles

Tires in different stages of finishing.

After all turning was done the tires were flat spotted as mentioned earlier and finishing could begin. Multiple coats of sealer were applied and sanded before priming and filling could begin.

To reach the final finish as shown in the first picture of this post – on the yellow towel – it took numerous meticulous sanding/filling/sanding/primer cycles to get them right.

The primary culprit creating the finicky work was the lips on the inside diameter (ID) and the OD. Blending the curve into the tiny flats was time-consuming.

WHEEL RIMS/CENTERS/KNOCK OFF NUTS

Lots of parts in various stages of refurbishing.

While the tires were being worked on the wheels were also in progress. The original 1983 sculpture had one-piece wood wheels and rims. Over 40 years later the paint on the rims started to crack so I fabricated them as two pieces this time - poplar tires and acrylic rims.

The original wheel centers were in good shape but needed new paint. Each center was made from a center hex with six spokes. Each spoke was shaped and the taller sides added separately. That’s 19 pieces per center.

The knock off nuts were also stripped of cracking original paint, and one broken ear was glued back in place. Then there was a lot of filling and sanding to make them right again before repainting.

Assembled wheel centers and rims during the painting process.

The new rims have been assembled with the refurbished centers and painting is in progress.

They’re close to being done.

Acrylic wheel rims turned using accurate CAD drawings.

Detailed CAD drawings were done to guide turning the rims. Slight modifications were made based on more abundant reference materials due to the internet.

Acrylic is a wonderful material to work with on the lathe. The material cuts smoothly and the results are beautiful.

Each wheel center’s OD has been carefully matched to a specific rim.

Wheel center and knock off nuts during old paint removal.

Scraping off all the old paint was difficult. All the tight corners were tricky, and any scrapes or divots had to be refilled and sanded.

Each knock off nut is about 1” (2.5 cm) in diameter with three separate ears shaped and glued in position. More fine scraping, filling, and sanding were needed before they were ready for new paint.

Finished knock off nuts.

The knockoff nuts are finished and ready for installation.

They may be some of the smallest parts on the T70, but they are still valuable contributors to the overall stance of the car.

Stance does matter.