The finished piece looking fine. Overall length is just over 12" (305mm ) which makes it approx 1:16 scale. Love the side dump exhausts! They'll burn off your pants leg cuffs in a hurry.

This Co-Hog was commissioned by Bill Doyle from Petersen Tractor to commemorate his SCCA #53 Trans-Am race car that he requested Huffaker Engineering to build for him in 1983. That car was nearly totaled at the 1984 SCCA National Runoffs when he was the tenth of 18 cars to succumb to a massive rain dump at turn six at Road Atlanta.

It was rebuilt for the 1985 season when Bill finished in the top 10 in the 4 races he ran and completed the season 18th overall.

Bill asked me to make the Pontiac in November, 1984 and it was completed in September, 1985. We had a wonderful dinner with Bill and his wife on a trip to CA after it was done. Great people!

photo credits: color - John Owens Photography - b&w - my own, taken as the piece was built

Most of the bits and pieces needed to make the wheels and tires. Photo-etched brass wheel centers made from my inked t-square, triangles and compass drawings. Five layers of 0.012" ( 0.3mm) were needed for each wheel.

Done before home computers when experience and a steady hand counted for a lot. Centers for a previously commissioned 280ZX Trans-Am race car are also shown.

Components were ready for final assembly. Exhaust pipe pair was fabricated from brass tubing. Wheel centers were constructed from a lamination of five layers of brass with a turned brass center. Wheel rims and center hubs were turned and polished aluminum and the tires were turned and painted cast acrylic.

Painting was completed and finish wet sanded. Windows, other graphics and tail lights were added using hand cut Scotchcal and vinyl. Here the #53 graphics were being added, each was 3 layers; white as a base, yellow and then black.

My hand-drawn ink drawings were used to make film negatives. The negs were then used to make pressure-sensitive Chromatecs. This was before I could make them myself so they were made by a typography firm. Applying the Chromatechs over the compound hood surfaces was tricky.

Next it was back into the spray booth for several finish coats of catalyzed clear to seal in all the graphics and give a great gloss.

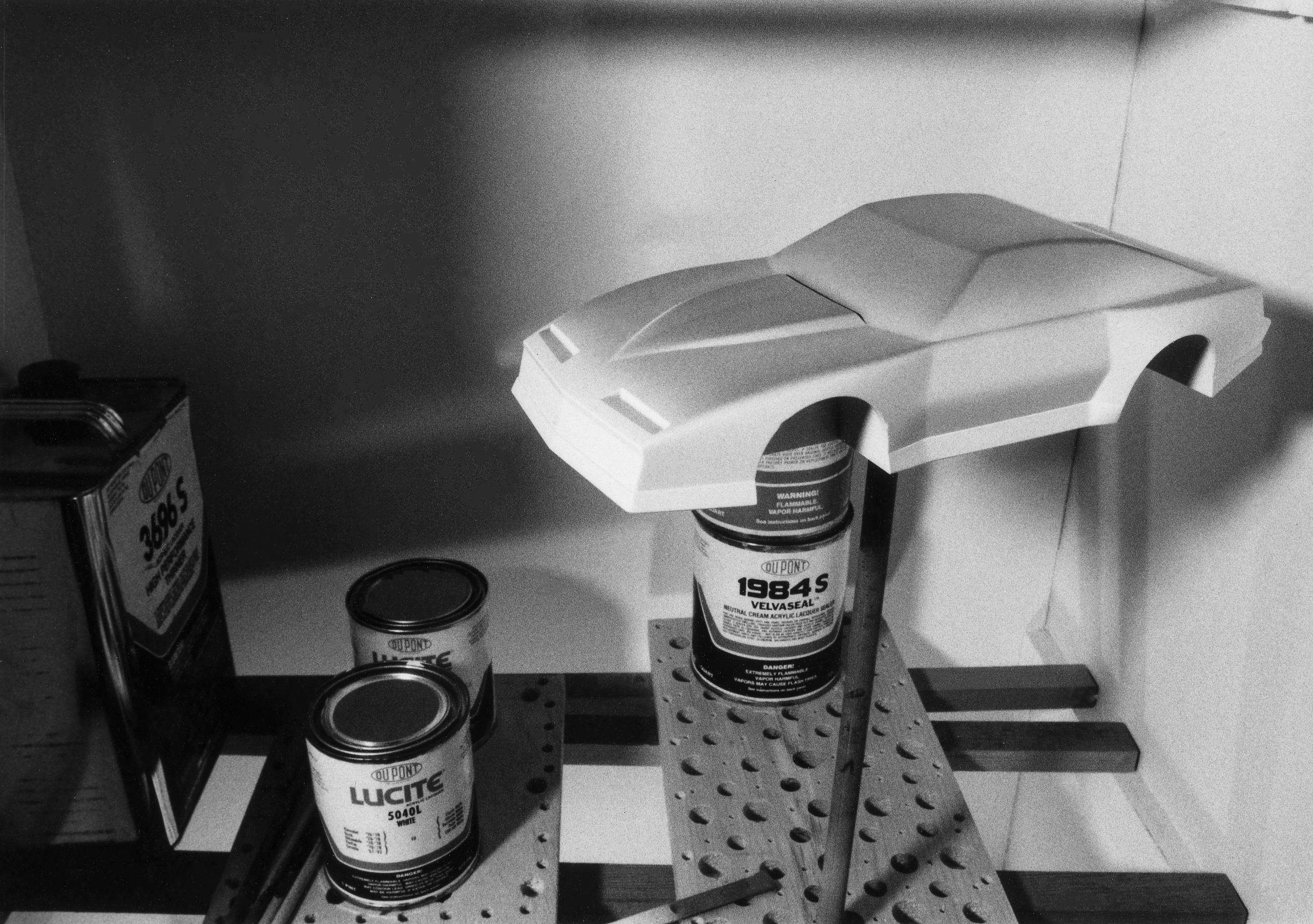

Automotive acrylic enamel colors to match the actual race car were used. I switched from acrylic lacquers shown here because the thinner caused swelling problems. Specific shades of blue and yellow came from the Petersen Tractor service trucks. Yellow and white stripes were each masked and sprayed.

That was a lot of taping and masking to get them right.

Priming is well on its way. It was time to make the rear spoiler by cutting it from aluminum sheet with a coping saw and bending it up.

A separate wing element visible in the color shot is made out of sheet styrene.

During sanding, shape refinements were regularly made with constant reference to the limited number of photos. If bare wood was exposed the surface was built back up again with sealer, primer and filler.

After every layer of primer surface imperfections were filled. This was one of the first cycles with seemingly more filler than primer.

The stance has been firmly established after progress on the wheels and tires. Body shape has been finalized and sealed, it's ready for an infinite number of priming, filling and sanding cycles.

Making progress, greenhouse and the top body layer are glued together. Once the fender flares were built from several pieces and pre-shaped, the bottom two body layers were glued together and the flares were blended into the body.

Aluminum and cast acrylic blanks ready for turning. Body was separated into three layers, the stack was joined with screws for alignment and easy disassembly during fabrication.

Started out with jelutong wood blocks cut and glued using my now-standard butterfly method to have a consistent centerline to work to.

Original pencil side-view drawing. A few other detail drawings were done as needed. The layered construction concept was figured out and construction started.

No computer, no CAD - just basic dimensions and a few pictures to go by. Have learned more about the race car now with the internet than I knew at the time through calls, letters and shared photos.